Customer needs research

The wheel design process always begins with a consultation with the client, defining their needs and budget. We determine the wheel’s style, type (modular or bolt-on), color, finish, and intended use (show car, everyday car, performance/racing car).

Depending on the client’s knowledge and vision, we always make every effort to advise the client on the best possible configuration, both visually and technically.

Pattern selection, measurements and parameterization

Once we understand the client’s vision, it’s time to gather all the necessary technical knowledge to properly configure the wheel. We determine the bolt pattern, the optimal offset (ET) from the wheel hub, the diameter, and the width. When selecting designs, we also pay close attention to load capacity—a wheel for a performance car or SUV must meet slightly different requirements.

In the case of cars with non-standard (e.g. aftermarket) braking systems, we also perform precise measurements of the brake calipers to ensure adequate clearance between the rim spokes and the caliper (so-called brake clearance). It is worth adding here that we are one of the few companies in Europe that offer a D2D measurement service.

Once we have all the necessary technical information, we proceed to the stage of selecting the base pattern (or designing a new rim from scratch).

3D design, 3D visualizations

The next stage is 3D modeling. This process is divided into the conceptual stage and the engineering stage. During the conceptual stage, based on information previously collected from the client, we prepare a wheel design in the color scheme of their choice. We also create a series of renderings (3D visualizations) depicting the wheel on the client’s vehicle.

Quality control and production

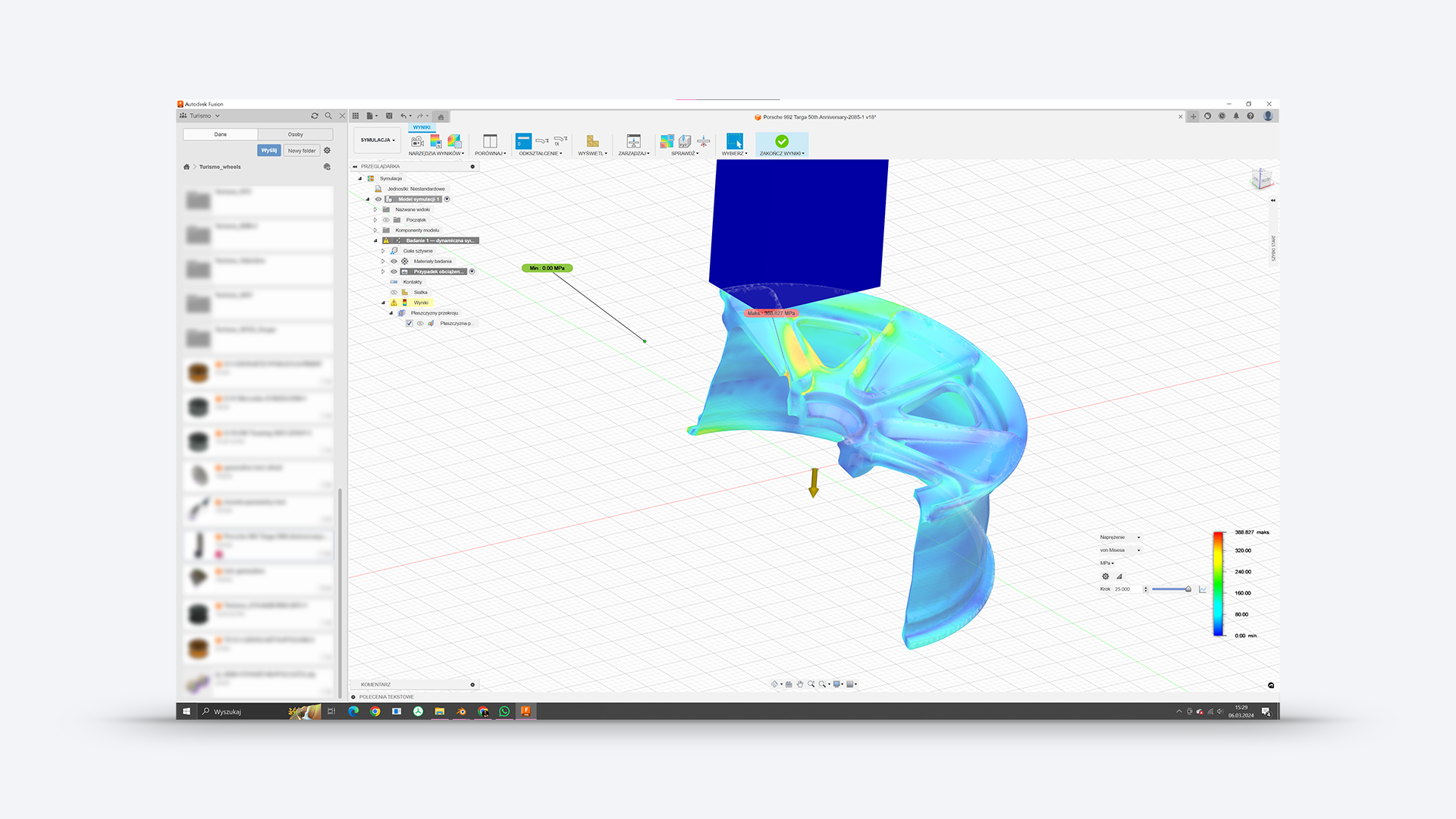

Based on the visualizations, the customer makes a purchasing decision. At this point, the wheel design is sent to our factory, where the 3D design undergoes additional testing before production begins.

With the implementation of the ISO9001 Quality Management System, a multi-stage quality control process was introduced to ensure the highest possible quality of wheels. This began with detailed verification of suppliers, their components, and prefabricated parts, all the way to milling and painting.

All aspects related to the structure’s safety are verified, and additional computer simulations are conducted to identify structural weaknesses. The mechanical properties of the rim are also checked for strength. Virtual FEM (Finite Element Method) simulations conducted using ANSYS software are identical to real-world rim tests performed for certification purposes.

Once the 3D model passes quality control, actual production begins using multi-axis CNC machines. After milling, grinding, and painting, the wheels are ready for shipment to our headquarters. However, before they reach the end customer, all products undergo multi-stage quality control and testing, such as checking the wheel’s radial runout.

We focus on quality

We make every effort to ensure that Turismo wheels are always crafted with attention to the smallest detail, that the production process runs smoothly, and that the end result fully meets customer expectations. Thanks to our years of experience and established standards, we can guarantee the highest quality, which has won the appreciation of countless automotive enthusiasts.